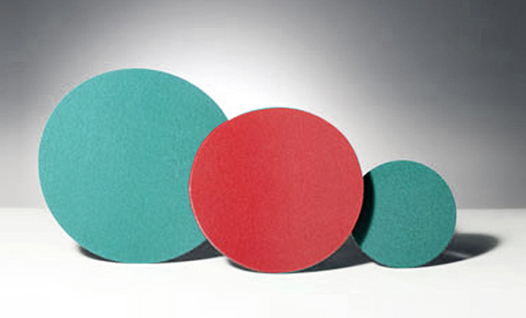

Sunfoam is made with fabric and foam structure to provide outstanding finish and even surface pressure. Special abrasives coating on the fabric allows sanding and polishing at same time to finish your work much faster. It is great for curved and contour surfaces and works well on wet sanding.

| Specification | |

|---|---|

| Grain | Sunfoam – Aluminum Oxide Sunfoam SC – Silicon Carbide |

| Backing | Fabric on Foam |

| Bond | Resin over Resin |

| Coating | Special coating on fabric |

| Grit range | 360 – 5000 |

| Type | Download |

|---|---|

| Image | download |

| Catalog | download |

| TDS | download |

| SDS | download |

Application

Automotive

Automotive Marine

Marine Aerospace

Aerospace Wood

Wood Metal

Metal

Type

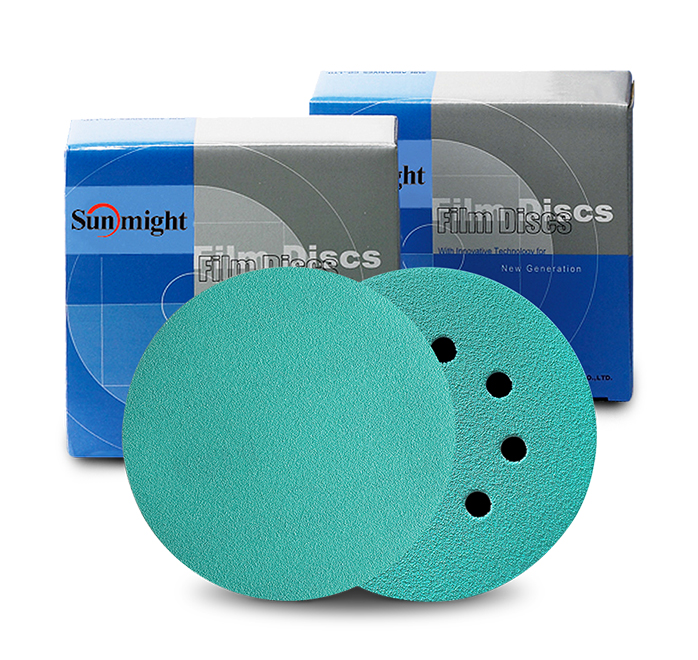

Disc

Disc

Grit range

| Product | P360 | P500 | P800 | P1000 | P2000 | P3000 | P5000 |

|---|---|---|---|---|---|---|---|

| Sunfoam | ● | ● | ● | ● | ● | ● | ● |

| Sunfoam SC | ● | ● | ● |

Product Benefit

- New Innovation of Finishing

-

Fabric and foam structure

- · Provide a better finish without deep scratch

- · Provide even surface pressure

- · Good for wet sanding

- · Good for contour or curved sanding

-

Special abrasive coating on the fabric

- · Allows grinding and polishing at the same time

: Reduces the compound polishing time (Clear Coat finishing)

: Makes a desirable gloss much faster (Solid surface finishing)

- · Allows grinding and polishing at the same time

-

Main Applications and Recommended Steps

- · Clear Coat : Removing orange peel or paint runs (Wet sanding)

6" Film disc6" Sunfoam#1500 grit>#3000 grit>Compound>Polish

6" Film disc6" Sunfoam#1500 grit>#3000 grit>Compound>Polish#3000 sunfoam drastically reduces the compound time

#1500 grit>#3000 grit>#5000 grit>Polish#5000 grit sunfoam may eliminate the compound process for small areas

· Suggested to use with Soft Backing Pad(08500) and interface pad (09600)

- · Automotive Headlights : Refurbishing the gray old headlights (Wet sanding)

3" Film disc with interface pad3" Sunfoam#500 grit>#800 grit>#3000 grit>Compound

3" Film disc with interface pad3" Sunfoam#500 grit>#800 grit>#3000 grit>Compound - · Solid Surface : Matte, Semi Gloss, High Gloss finish (Wet or Dry sanding)

6" Film disc6" Sunfoam discMatte Finish :#180>#320>#240Semi Gloss Finish :#180>#320>#240>#500High Gloss Finish :#180>#320>#240>#500>#2000>#3000

6" Film disc6" Sunfoam discMatte Finish :#180>#320>#240Semi Gloss Finish :#180>#320>#240>#500High Gloss Finish :#180>#320>#240>#500>#2000>#3000 - · Others : Furniture, Instruments, Bowling balls, Plastics, etc.

- · Clear Coat : Removing orange peel or paint runs (Wet sanding)

-

Difference between Sunfoam and Sunfoam SC

- · Sunfoam for better finishing

- · Sunfoam SC for improved cutting performance and life